Mini Breweries

1. Subject of the offer

The subbject of this offer is a minibrewery with annual output of 500 – 20.000 hl beer/year. The main important parts of technological equipment are products of Czech manufacturer with more than 100 years of tradition in manufacturing food industry machinery.

Measuring and regulation systems (if required by the customer) are supplied by famous overseas

companies.

The PIVO Praha, s.r.o.(Ltd.) company establishes the entire engineering from project elaboration to putting the brewery in operation by test charges.

2. Principal technical requirements

1. Rooms

| Output of the Brewery: 500 hl/year | Area: 50 – 70 m2 |

| Output of the Brewery: 1 000 hl/year | Area: 80 – 100 m2 |

| Output of the Brewery: 1 500 hl/year | Area: 90 – 110 m2 |

| Output of the Brewery: 3 000 hl/year | Area: 130 – 150 m2 |

| Output of the Brewery: 5 000 hl/year | Area: 180 – 220 m2 |

| Output of the Brewery: 10 000 hl/year | Area: 300 – 350 m2 |

| Output of the Brewery: 20 000 hl/year | Area: 450 – 500 m2 |

| Height of rooms: up to 1.500 hl/year – brewhouse | min 3,0 m |

| Height of rooms: – the others | min 3,0 m |

| Height of rooms: over 1.500 hl/year: – brewhouse | min 3,5 m |

| Height of rooms: – the others | min 3,5 m |

2. Energy

a) El.energy – 3 x 380 / 220 V, 50 Hz

| Total supply installed: up to 1.500 hl/year | 45 kW |

| over 1.500 hl/year – according to the type of heating of the brewhouse | from 35 to 220 kW |

b) Other sources of energy for heating the brewhouse for capacity over 1.500 hl/year:

| external steam source | 200 kg/h |

| earth gas | 23 m2/h |

| diesel | 19 kg/h |

| electric power | 180 kW |

3. Principal raw materials

| Water | Consumption | 4 – 5 hl water / hl beer |

| Resource efficiency | whithout recovery – min. 1,0 l/s | |

| Resource efficiency | with recovery min. 0,3 l/s | |

| Quality | hardness – max. 12 on | |

| Rest water | 3 – 4 hl/hl beer | |

| Rest water | BOD5 – 1,0-5,0 kg.m-3 | |

| Pilsner malt | Consumption | l8 kg/hl |

| Hop granulated | Consumption | 300 g/hl (partial replacement by hop extract possible) |

| Yeast | Consumption | 0,1 l/hl |

4. Additional instruction for customer

For selection of the optimal technical-technological version and to specify the delivery and price, the following data are decisive:

- Initial volume of production

- Maximal volume of production

- Season differences (summer, winter)

- Automation level (manufacturing, half, completely)

- Number of types of beer produced

- Ways of sales (in pub only, barrels, bottles)

- Construction blueprints

- Chemical analyses of water

3. Equipment description

The delivery represents a fundamental module, which can be corrected according to specific requirements of the customer. It comprises all the necessary units for production of Pilsner type of beer designed for particular annual sale.

Delivery specification

1. Two-cylinder crushing mill

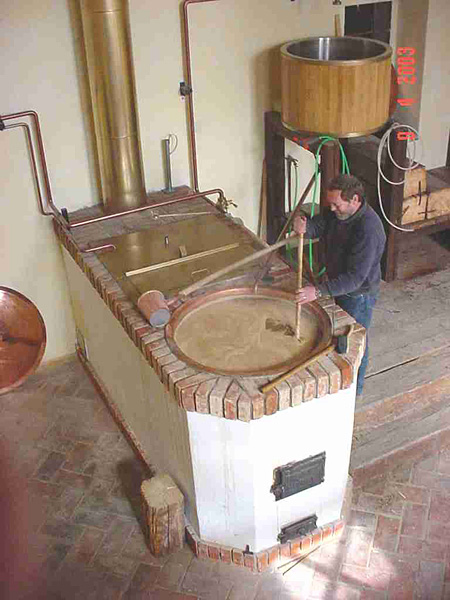

2. Brewhouse in copper, size 5, 10, or 20 hl/charge

3. Whirling vessel

4. Plate cooler

5. Hot water container

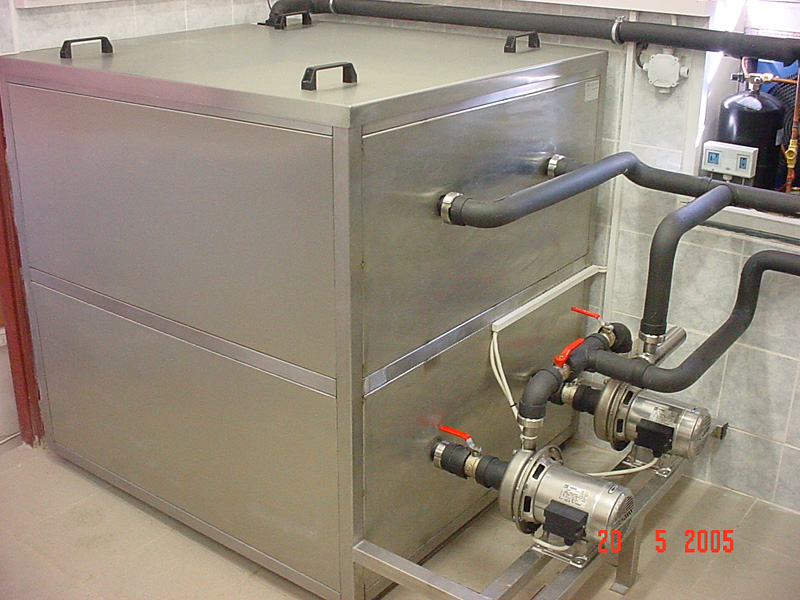

6. Fermentation and storage cylindroconic tanks in stainless steel

7. Yeast treatment units

8. Tap-room tank in stainless steel

9. CIP vessel

10. Pumps

11. Air compressor (inclusive the aeration system)

12. Cooling system for the tanks

13. Pipes and fittings

14. Basic measuring and regulation module

15. Engineering comprising the elaboration of technological project

16. Supervising the assembling, putting into service and staff training

Conditions of transport:

500 hl/year – 2 containers weight of delivery – 6 t

1 000 hl/year – 3 containers weight of delivery – 8 t

1 500 hl/year – 3 containers weight of delivery – 10 t

3 000 hl/year – 4 containers weight of delivery – 15 t

5 000 hl/year – 6 containers weight of delivery – 20 t

10 000 hl/year – 13 containers weight of delivery – 35 t

20 000 hl/year – 14 containers weight of delivery – 45 t

4. Price

200 000 – 1 000 000 EUR

The delivery does not comprise:

- assembling

- building project

- building and adaptation of the site

- transport

- packages

- utility lines to the object

- traveling and accommodation costs at site

According to customer’s demands the offer may be as an”extra” price completed by:

- steam generator (electric, light oil, gas) – including attaching pipelines

- beer filtration

- bottling

- barreling

- automation, measurement, regulation

- rooms cooling

- auxiliary facilities and equipment (balances, containers for brewer°s grains, laboratory facilities, water treatment and recovery etc.)

- staff training on similar equipment in the Czech Republic

- special sorts of beers know-how

5. Terms of delivery

Terms of delivery is 3 – 6 months from the date of the conclusion of an agreement.