Piko Breweries

100 – 500 hl / year

The pikobrewery installations task is beer production in home conditions, in small bars and for production of own beer as supplemently assortment of big pubs. This works enable production of all kinds of beer including the traditional technology used by majority Czech breweries. The equipment is for two beer type.

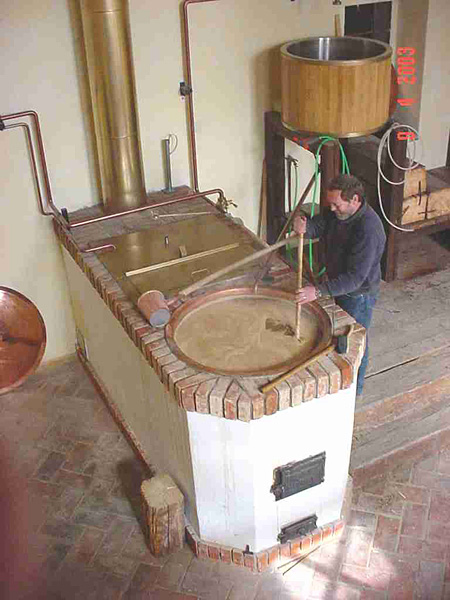

1. Brewhouse

The brewhouse contains two vessels, the volume of wort is 110 or 250 litres, the cylinder part and bottom are made of stainless steel, the coverings and other parts are of copper.

Brewhouse with volume 110 litres is determined for brewery with output 100 – 250 hl beer annualy, brewhouse with volume 250 litres for brewery with output 300 – 500 hl annualy.

Mash and wort kettle

Heating : electric energy or steam 0,4 MPa, 30 kg / h

Mixing : by round with the help of a pump with regulatable turnings

Lauter tun

lautering by means of a pump with regulatable turnings

Pipe line with fitings, condensator of steam

Brew vessels are put in construction, the part of which is a counter with a tap desk and basin. The brewhouse facing can be chosen according to the concrete interier either with wood or ceramics.

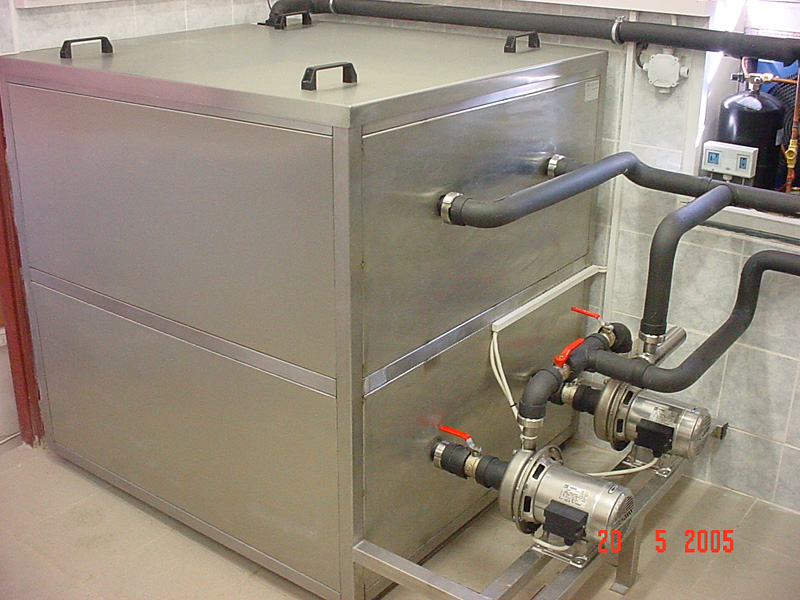

2. Cooling

The wort cooling is ensured in accordance with the chosen variant by a two – degree or one – degree plate cooler.The cooling of the coolers second section as well as of the fermentary tubs is provided by the cooling producer. The aeration of wort is provided by the aeration candle.

Plate cooler: a two-stage or one-stage

Airation candle: stainless steel

3. Main fermentation

The main fermentation takes part in the fermentation vessels with the volume of 120, 250 or 500 litres

Fermentation vessel

volume 120, 250 or 500 litres, stainless steel

Cooling box

stainless steel, automatic temperature regulation, for the production mor then 250 hl / year polyuretan plastic box

Cool producer

volume 100-200 litres, automatic temperature regulation

4. Lagering, taping of the beer

Beer is maturated in 50 l, 100 l KEG barrels, 500 l lager tanks in a cooling box. The overpressure regulation is provided by the adapted KEG fittings

cooling box: made of stainless steel, automatic temperature regulation, for the production more then 250 hl / year polyuretan plastic box

KEG barrels: volume 50 or 100 litres, for lagering and taping

Lager tanks: volume 500 l

Adapted KEG fittings: overpressure regulation, manometre

Bright beer tanks: volume 500 l, for output more as 250 hl/year

5. Malt mill

output 50 kg / h

6. Water tank

with electroheaiting, insulation

7. Air compresor

output 2 m 3 / h

Area for the brewery

| output | hl beer / year | 100 | 200 | 500 |

| area | m2 | 40 | 50 | 70 |

Price

100 000 – 200 000 EUR

Terms of delivery

3-4 months since the contract signing

Transport of brewery with output max. 250 hl annualy in 1 20´ container, brewery with bigger output in 1 40´ container including raw material for first 4 brews. Weight of delivery is max 5 000 kg.

The offer helps the customer to be better informed about the main items. For a concrete offer more information is needed as following:

- annual beer output

- produced beer brands (1 – 2 optimum)

- demands for complementing works